Lihlahisoa

-

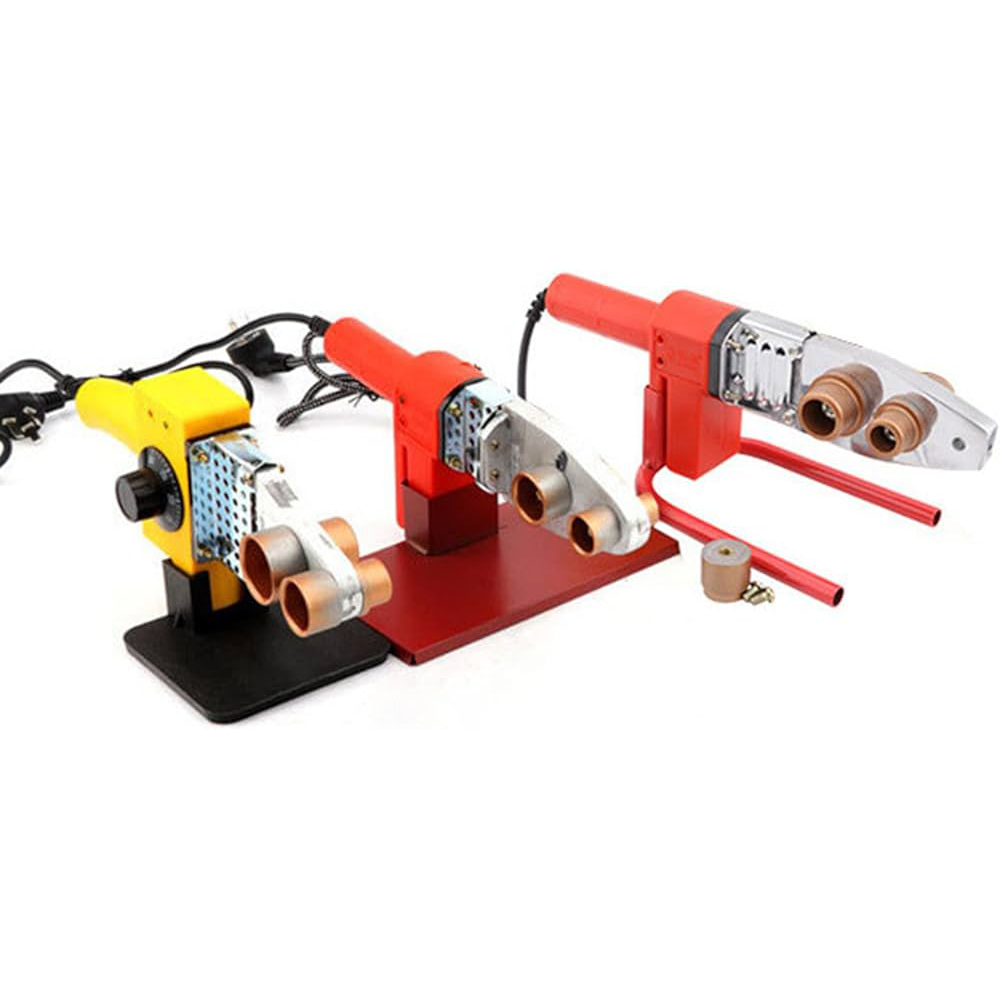

Phetoho e Etsang Hore ho Kenye Lipeipi Tsa Plastiki: Karolo ea Mechini ea ho Welding ea Pipe ea Plastiki e Ikemetseng

Makaleng a ntseng a tsoela pele ka potlako a kaho le a indasteri, ho hlahile mechini ea othomathike ea liphaephe tsa polasetiki e le lisebelisoa tsa bohlokoa, tse fetolang tsela eo liphaephe tsa polasetiki li kenngoang le ho hlokomeloa ka tsona. Mechini ena e tsoetseng pele e iketsetsa ts'ebetso ea ho tjheseletsa, ho netefatsa hore li-welds tsa boleng bo holimo, tse sa fetoheng tse fokotsang haholo monyetla oa phoso ea motho. Tataiso ena e felletseng e shebana le lefats'e la mechini ea othomathike ea lipeipi tsa polasetiki, e fanang ka leseli mabapi le ts'ebetso ea eona, melemo, le katleho eo e e tlisang mererong.

-

Ho Tsamaisa Lefats'e la Thepa ea Plastic Pipe Welding Equipment: Tataiso e Pharalletseng

Ho tjheseletsa lipeipi tsa polasetiki ho eme e le lejoe la motheo kahong le tlhokomelong ea letoto le leholo la liphaephe tse hlokahalang bakeng sa ho tsamaisa metsi, khase le lik'hemik'hale. Tsoelo-pele ea lisebelisoa tsa ho cheselletsa lipeipi tsa polasetiki li fetotse tsela eo mesebetsi ena e etsoang ka eona, e fana ka ho nepahala, ho sebetsa hantle le ho tšepahala. Tataiso ena e shebana le lintlha tsa bohlokoa tsa lisebelisoa tsa ho tjheseletsa lipeipi tsa polasetiki, ho thusa litsebi ho etsa liqeto tse nepahetseng bakeng sa litlhoko tsa bona tsa ho cheselletsa.

-

Ho Potlakisa Merero ea Liphaephe: Melemo ea Thepa ea Polastiki ea Welding e potlakileng

Libakeng tsa kajeno tsa kaho tse potlakileng le tsa indasteri, hangata nako ke ea bohlokoa. Ho fihla ha lisebelisoa tsa liphaephe tsa polasetiki tse chesellang ka potlako ho tšoaea ho tlola ho hoholo, ho fana ka motsoako oa lebelo, katleho le ts'epahalo. E etselitsoe ho fihlela litlhoko tsa merero e hlokang ho phethoa ka potlako ntle le ho sekisetsa boleng, lisebelisoa tsena tse tsoetseng pele li fetola tsela eo lipeipi tsa polasetiki li kenngoang le ho lokisoa ka eona. Tataiso ena e hlahloba lefatše le tsoetseng pele la lisebelisoa tsa liphaephe tsa polasetiki tse chesellang ka potlako, e fana ka leseli mabapi le ts'ebetso ea eona, melemo le katleho eo e e tlisang mererong.

-

Ho Phahamisa Polasetiki: Phetoho ea Thepa ea Handheld Plastic Fusion Equipment

Lefatšeng la litokiso le kaho ea polasetiki, lisebelisoa tsa ho kopanya polasetiki tse tšoaroang ka letsoho li tšoaea mohato oa bohlokoahali, tse fanang ka ho nepahala, ho sisinyeha le ho sebelisoa habonolo. Lisebelisoa tsena tse kopaneng li entsoe ho fihlela litlhoko tsa litsebi le ba chesehelang DIY ka mokhoa o ts'oanang, li fana ka tharollo e sebetsang bakeng sa ho kopanya lisebelisoa tsa polasetiki ntle le moroallo. Tataiso ena e felletseng e kenella ka har'a lintho tsa bohlokoa tsa lisebelisoa tsa ho kopanya polasetiki ka letsoho, e bonts'a phello ea eona ea phetoho mererong ea litšepe tsa polasetiki.

-

The Ultimate Guide to Multipurpose Plastic Welding Tools: Versatility at Its Best

Sebakeng se ntseng se tsoela pele sa ho etsa le ho lokisoa ha polasetiki, lisebelisoa tse ngata tsa ho cheseletsa tsa polasetiki li hlahile e le thepa ea bohlokoahali, e kopanyang ho feto-fetoha ha maemo le katleho. Lisebelisoa tsena tse akaretsang li entsoe ho sebetsana le mesebetsi e mengata e fapaneng ea li-welding, e leng se etsang hore e be ntho e hlokahalang bakeng sa litsebi le batho ba ratang ho itlosa bolutu ka ho tšoana. Tataiso ena e batsi e shebana le lefats'e la lisebelisoa tsa ho cheseletsa polasetiki tse ngata, tse fanang ka leseli mabapi le ts'ebetso ea tsona, melemo, le hore na li fetola tsela eo re sebetsang ka eona ka polasetiki.

-

Phetoho ea Merero ea Liphaephe: Ho phahama ha Lisebelisuoa tsa ho Welding Pipe ea Plastiki e Bonolo

Sebakeng se matla sa ho kenya le ho lokisoa ha liphaephe tsa polasetiki, ho fihla ha lisebelisoa tsa ho tjheseletsa liphaephe tsa polasetiki tse bobebe ho tšoaea phetoho e kholo, ho kopanya bokhoni le ts'ebetso e matla. Lisebelisoa tsena li entsoe ho fihlela litlhoko tsa litsebi le ba chesehelang DIY ka mokhoa o ts'oanang, li fana ka tharollo e sebetsang bakeng sa ho etsa liphaephe tse nepahetseng le tse tšoarellang. Tataiso ena e hlahloba lintlha tsa bohlokoa tsa lisebelisoa tsa ho tjheseletsa liphaephe tsa polasetiki tse bobebe, ho totobatsa phello ea bona ea phetoho mererong ea liphaephe.

-

Ho Matlafatsa Tlhahiso ea Sejoale-joale: Ho Theoha ka botebo ka har'a Lisebelisoa tsa Welding tsa Plastiki tsa Indasteri

Lefatšeng le ntseng le tsoela pele ka potlako la tlhahiso ea liindasteri, thepa ea ho cheselletsa polasetiki e fetohile theknoloji ea lejoe la sekhutlo, e nolofalletsang ho etsoa le ho lokisa likarolo tse ngata tsa polasetiki ka ho nepahala le ka katleho. Tataiso ena e felletseng e hlahloba lefatše le rarahaneng la lisebelisoa tsa li-welding tsa polasetiki tsa indasteri, e fana ka leseli mabapi le karolo ea eona ea bohlokoa liindastering tse fapaneng, lisebelisoa tse fapaneng tse fumanehang, le lintlha tsa bohlokoa tsa ho khetha lisebelisoa tse nepahetseng bakeng sa litlhoko tsa hau tsa tlhahiso.

-

Phetoho ea Phetoho ea Plastiki: Ho hlaha ha Mechini ea Welding ea Plastiki ea CNC

Sebakeng sa ho tjheseletsa ka polasetiki, ho tla ha metjhini ya tjheseletsa ya polasetiki ya CNC ho emela ho tlola ho hoholo, ho kopanya boenjineri bo nepahetseng le thekenoloji ya dijithale. Litsamaiso tsena tse tsoetseng pele li fana ka ho nepahala ho ke keng ha bapisoa, ho sebetsa hantle le ho pheta-pheta ts'ebetsong ea ho tjheseletsa, ho etsa hore e be tsa bohlokoa haholo bakeng sa indasteri e hlokang tjheseletsa ea polasetiki ea boleng bo holimo. Tataiso ena e felletseng e shebana le mechini ea tjheseletsa ea polasetiki ea CNC, e bonts'a melemo ea eona, lits'ebetso, le hore na ba theha bokamoso ba polasetiki joang.

-

Phetoho ea Phetoho ea Lipeipi tsa Plastiki: Ho phahama ha Mechini ea Welding ea Plastic Pipe

Libakeng tsa kaho le tlhahiso e ntseng e tsoela pele ka potlako, tlhokahalo ea litharollo tsa lipeipi tsa polasetiki tse sebetsang hantle haholoanyane, tse tšepahalang le tse nepahetseng li lebisitse tsoelopeleng e kholo ea theknoloji ea ho tjheseletsa. Har'a tsena, mechine ea ho tjheseletsa liphaephe tsa polasetiki e iketselitseng e hlahella e le batho ba fetolang lipapali, e fanang ka katleho e ke keng ea lekanngoa le ho tsitsisa mesebetsing e phahameng ea li-welding. Tataiso ena e felletseng e lekola likarolo tsa morao-rao, melemo, le lintlha tse tebileng tsa mochini o tjheseletsang lipeipi tsa polasetiki, e matlafatsang likhoebo ho etsa liqeto tse nepahetseng bakeng sa merero ea bona ea ho kenya liphaephe tsa polasetiki.

-

Ho Tseba Tsebo ea ho Etsa Plastic Fabrication: Tataiso ea Manual Plastic Welding Equipment

Lefatšeng le fapaneng la ho etsa le ho lokisa thepa ea polasetiki, lisebelisoa tsa ho tjheseletsa tsa polasetiki li hlahella ka ho fana ka ho nepahala, ho khoneha le ho ikamahanya le maemo. E loketse litsebi tse nang le boiphihlelo le ba chesehelang DIY, lisebelisoa tsena li thusa basebelisi ho etsa mosebetsi o felletseng oa lisebelisoa tse fapaneng tsa polasetiki tse nang le taolo e felletseng ea ts'ebetso ea ho cheselletsa. Tataiso ena e felletseng e shebana le lintlha tsa bohlokoa tsa lisebelisoa tsa ho cheselletsa polasetiki ka matsoho, e u thusa ho utloisisa melemo ea eona, lits'ebetso, le mokhoa oa ho khetha lisebelisoa tse nepahetseng bakeng sa merero ea hau.

-

Ho notlolla ho Fetoha ha Mahlale: Ho phahama ha Mechini ea ho Welding ea Plastic

Lefatšeng le matla la ho etsa le ho lokisa polasetiki, metjhini e nkehang ea tjheseletsa ea polasetiki e fetoha lisebelisoa tsa bohlokoahali. E fana ka motsoako o phethahetseng oa ho tsamaea, ho sebetsa hantle, le ho nepahala, mechini ena e matlafatsa basebelisi ho sebetsana le merero e mengata habonolo. Hore na o setsebi se sebetsang sebakeng sa marang-rang kapa motho ea chesehelang mosebetsi oa DIY ea qalang morero oa lapeng, ho utloisisa bokhoni le ho khetha mochini o nepahetseng oa polasetiki o nkehang oa tjheseletsa ho ka phahamisa boleng ba mosebetsi oa hau haholo. Tataiso ena e hlahloba lintlha tsa bohlokoa tsa lisebelisoa tsena tse ncha, e u thusa ho feta likhethong tsa hau.

-

Tataiso ea Bohlokoa ho Thepa ea Plastic Pipeline Welding: Mefuta, Khetho, le Mekhoa e Metle ka ho Fetisisa.

Liphaephe tsa polasetiki ke karolo ea liindasteri tse ngata, tse tsamaisang ntho e 'ngoe le e 'ngoe ho tloha metsing ho ea lik'hemik'haleng ka mokhoa o sireletsehileng le ka mokhoa o atlehileng. Senotlolo sa ho tšepahala ha tsona ke boleng ba kaho le tlhokomelo ea tsona, moo lisebelisoa tsa ho tjheseletsa liphaephe tsa polasetiki li phethang karolo ea bohlokoa. Tataiso ena e fana ka leseli mabapi le ho khetha le ho sebelisa lisebelisoa tse nepahetseng bakeng sa liphaephe tsa polasetiki tse chesellang, ho netefatsa likhokahano tse tšoarellang le tse sa duleng.