Phetoho ea Phetoho ea Lipeipi tsa Plastiki: Ho phahama ha Mechini ea Welding ea Plastic Pipe

Ho Utloisisa Mechini ea Welding ea Plastiki e Ikemetseng

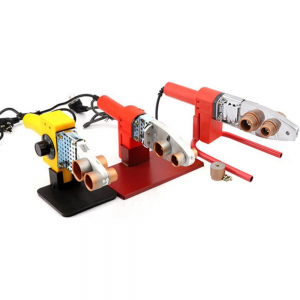

Mechini ea othomathike ea liphaephe tsa polasetiki ke lisebelisoa tse tsoetseng pele tse etselitsoeng ho tsamaisa mokhoa oa ho tjheseletsa oa liphaephe tsa thermoplastic, joalo ka polyethylene (PE), polypropylene (PP), le polyvinyl chloride (PVC). Mechini ena e kopanya mocheso, khatello le mekhahlelo ea ho pholisa tlas'a taolo e nepahetseng, ho netefatsa litšepe tsa boleng bo holimo tse nang le ts'ebetso e fokolang ea motho. Ho tloha ho nts'etsopele ea meaho ho isa lits'ebetsong tsa ts'ebeliso, mechini ea othomathike ea li-welding e ntse e hlokahala haholo liindastering tse fapaneng.

Likarolo tsa Bohlokoa le Melemo

●Nepahetseng le ho tsitsisa: Mekhoa ea ho laola e ikemetseng e netefatsa hore weld e 'ngoe le e' ngoe e etsoa ka litekanyetso tse nepahetseng, ho fokotsa kotsi ea phoso ea motho le ho fetoha.

●Keketseho ea Tlhahiso: Ka lipotoloho tse potlakileng tsa li-welding le ho seta ka matsoho ho fokolang, merero e ka phethoa ka potlako, e ntlafatsa tlhahiso ka kakaretso.

●Ho rengoa ha data le ho Traceability: Mefuta e tsoetseng pele e fana ka bokhoni ba ho rengoa ha data, e lumellang basebelisi ho beha leihlo le ho rekota litekanyetso tsa welding bakeng sa netefatso ea boleng le merero ea ho latela.

●Sehokelo sa Mosebelisi: Ho sa tsotellehe ho rarahana ha eona, mechine ea morao-rao e na le li-interfaces tse hlakileng, e leng ho nolofalletsang basebetsi ho laola ts'ebetso ea li-welding.

Ho Khetha Mochini oa ho Welding oa Pipe ea Polastiki o Iketselitsoeng

Ho khetha mochini o tjheseletsang phala ea polasetiki o ikatisang ka ho fetesisa o hloka ho shebisisa lintlha tse 'maloa ka hloko:

●Boholo ba Pipe le Tšebelisano ea Lintho: Netefatsa hore mochini o ka amohela mefuta e mengata ea liphaephe le lisebelisoa tse sebelisoang mererong ea hau.

●Litlhoko tsa Ts'ebetso ea Welding: Mechini e fapaneng e fana ka lits'ebetso tse fapaneng tsa welding (mohlala, fusion ea butt, electrofusion). Khetha mochine o lumellanang le litlhoko tsa hau tse khethehileng.

●Portability le Maemo a Sebaka: Nahana ka motsamao oa mochini le ho ikamahanya le maemo a fapaneng a sebaka, haholo-holo bakeng sa merero e maemong a thata.

●Tšehetso ea Theknoloji le Tlhokomelo: Khetha bakeng sa bahlahisi ba fanang ka tšehetso e felletseng ea tekheniki le phihlello e bonolo ea lits'ebeletso tsa tlhokomelo ho netefatsa ts'epo ea nako e telele.

Likopo le Phello ea Indasteri

Mechini ea othomathike ea lipeipi tsa polasetiki e fetola ts'ebetso makaleng a kang taolo ea metsi le litšila, kabo ea khase le lits'ebetso tsa lipeipi tsa indasteri. Ka ho nolofatsa ts'ebetso ea ho cheselletsa, mechini ena ha e ntlafatse lebelo le boleng ba lits'ebetso feela empa hape e kenya letsoho bophelong bo bolelele le polokeho ea marang-rang a liphaephe.

Mekhoa e Molemo ka ho Fetisisa ea ho Phethahatsoa

Ho eketsa melemo ea mechini ea othomathike ea lipeipi tsa polasetiki, latela mekhoa e metle e latelang:

●Koetliso e Phethahetseng: Netefatsa hore basebetsi ba fumana koetliso e felletseng mabapi le mofuta o ikhethileng oa mochini oa welding ho ntlafatsa ts'ebeliso le tlhokomelo ea ona.

●Khafetsa Calibration le Tlhokomelo: Boloka mochine o le boemong bo phahameng ka ho lekanya kamehla le tlhokomelo ea thibelo, ho latela litlhahiso tsa moetsi.

●Taolo ea Boleng: Sebelisa lintlha tsa mochini tsa ho rema lifate ho lekola boleng ba weld le ho etsa liphetoho ha ho hlokahala ho boloka maemo a holimo.

Qetello

Ho fihla ha mechini ea tjheseletsa ea liphaephe tsa polasetiki ka boiketsetso ho bontša tsoelo-pele e kholo ea theknoloji ea ho kenya liphaephe tsa polasetiki. Ka ho amohela lisebelisoa tsena tse tsoetseng pele, likhoebo li ka fihlela ts'ebetso e phahameng, boleng le botsitso ts'ebetsong ea tsona ea ho cheselletsa, ho ipeha ka pele ho boqapi ba indasteri. Ha thekenoloji e ntse e tsoela pele ho fetoha, ho lula u tseba le ho tsetela ka thepa e nepahetseng e tla ba senotlolo sa ho sebelisa bokhoni bo felletseng ba ho iketsetsa liphaephe tsa polasetiki.