SDY355 BUTT FUSION tjheseletsa MACHINE OPERATIONS MANUAL

Tlhaloso e Ikgethileng

Pele a sebelisa mochini, mang kapa mang o lokela ho bala tlhaloso ena ka hloko le ho e boloka hantle ho netefatsa polokeho ea sesebelisoa le ts'ireletseho ea opareitara, hammoho le polokeho ea ba bang.

2.1 Mochini o sebelisetsoa ho cheseletsa liphaephe tse entsoeng ka PE, PP, PVDF 'me o ke ke oa sebelisoa ho cheselletsa thepa ntle le tlhaloso, ho seng joalo mochini o ka senyeha kapa kotsi e itseng e ka hlaha.

2.2 Se ke oa sebelisa mochini sebakeng se nang le kotsi ea ho phatloha

2.3 Mochini o lokela ho sebetsoa ke basebetsi ba nang le boikarabelo, ba nang le tsebo le ba koetlisitsoeng.

2.4 Mochini o lokela ho sebetsoa sebakeng se omileng. Mehato ea tšireletso e lokela ho nkoa ha e sebelisoa pula kapa mobung o mongobo.

2.5 Mochine o sebelisoa ke 220V±10%, 50 Hz. Haeba ho ka sebelisoa terata e atolositsoeng, e lokela ho ba le karolo e lekaneng ea loto ho latela bolelele ba eona.

2.6 Pele o sebelisa mochini, tlatsa 46# oli ea haeteroliki. Etsa bonnete ba hore oli ea hydraulic e lekane ho sebetsa; boemo ba oli e lokela ho ba 2/3 ea tanka. Tlosa sekoaelo sa tanka ea oli ea tšepe ka sekoaelo sa polasetiki se khubelu sa moea kapa khatello e ke ke ea tšoarella.

Polokeho

3.1 Hlokomela ha o sebelisa le ho tsamaisa mochini ho latela melao eohle ea polokeho ea taelo ena.

3.1.1 Hlokomela ha o sebedisa

l Mokhanni e lokela ho ba basebetsi ba nang le boikarabelo le ba koetlisitsoeng.

l Hlahloba le ho boloka mochine ka ho feletseng ka selemo bakeng sa polokeho le botšepehi ba mochine.

l Sebaka sa mosebetsi se litšila le se nang le makukuno se ne se ke ke sa fokotsa ts'ebetso ea ts'ebetso feela, empa se baka kotsi habonolo, kahoo ke habohlokoa ho boloka sebaka sa mosebetsi se hloekile 'me ho se na litšitiso tse ling.

3.1.2 Matla

Lebokose la kabo ea motlakase le lokela ho ba le sets'oants'o sa fatše se nang le maemo a nepahetseng a polokeho ea motlakase. Lisebelisoa tsohle tsa tšireletso li bonts'oa ka mantsoe kapa matšoao a utloisisehang habonolo.

Earthing: Sebaka sohle se lokela ho arolelana terata e le 'ngoe ea fatše le sistimi ea khokahanyo ea fatše e lokela ho phethoa le ho lekoa ke batho ba litsebi.

3.1.3 Ho hokeloa ha mochini ho matla

Mochini o kopanyang thapo ho matla e lokela ho ba concussion ea mochini le bopaki ba ho bola ha lik'hemik'hale. Haeba terata e atolositsoeng e sebelisoa, e tlameha ho ba le karolo e lekaneng ea ho etella pele ho latela bolelele ba eona.

3.1.4 Ho boloka thepa ea motlakase

Bakeng sa min. Likotsi, lisebelisoa tsohle li tlameha ho sebelisoa le ho bolokoa ka nepo ka tsela e latelang:

※ Qoba ho sebelisa mohala oa nakoana o sa tsamaellaneng le maemo

※ Se ke oa ama likarolo tsa electrophorus

※ Hanela ho hula thapo hore o hakoe

※ Hanela ho hula likhoele bakeng sa lisebelisoa tsa ho phahamisa

※ U se ke ua beha ntho e boima kapa e bohale holim'a likhoele, 'me u laole mocheso oa cable ka har'a mocheso o fokolang (70℃)

※ Se ke oa sebetsa sebakeng se metsi. Sheba hore na groove le lieta li omme.

※ Se ke oa fafatsa mochini

3.1.5 Nako le nako, hlahloba boemo ba mochini o kenang kahare

※ Lekola ho kenngoa ha likhoele haholo-holo lintlha tse fetisitsoeng

※ Se ke oa sebelisa mochini tlas'a maemo a feteletseng.

※ Sheba hore na sesebelisoa sa ho lutla se sebetsa hantle bonyane ka beke.

※ Lekola hore na mochini o sebetsa joang ka basebetsi ba tšoanelehang

3.1.6 Hloekisa le ho hlahloba mochini ka hloko

※ U se ke ua sebelisa lisebelisoa (tse kang abrasive, le solvents tse ling) tse senyang sekontiri habonolo ha u hloekisa mochine.

※ Etsa bonnete ba hore motlakase o khaotsoe ha o qeta mosebetsi.

※ Etsa bonnete ba hore ha ho na tšenyo leha e le efe mochineng pele o sebelisa hape.

Haeba feela ho latela se boletsoeng ka holimo, ts'ireletso e ka sebetsa hantle.

3.1.7 Ho qala

Etsa bonnete ba hore switch ea mochini e koetsoe pele o e bula.

3.1.8 Motho ea sa koetlisoang ha a lumelloe ho sebelisa mochine ka nako efe kapa efe.

3.2.Likotsi tse ka bang teng

3.3.1 Mochini oa fusion ea Butt o laoloang ke hydraulic unit:

Mochini ona o sebetsoa feela ke setsebi kapa ba bang ba nang le setifikeiti sa tšebetso, ho seng joalo kotsi e sa batleheng e kanna ea bakoa.

3.3.2 Letlapa le futhumatsang

Mocheso o phahameng oa mocheso o ka fihla ho 270 ℃, kahoo lintho tse latelang li lokela ho hlokomeloa:

------Apara liatlana tsa polokeho

-------Le ka mohla u se ke ua tšoara bokaholimo ba poleiti e futhumatsang

3.3.3 Sesebelisoa sa ho rala

Pele o kuta liphaephe, lipheletso tsa liphaephe li lokela ho hloekisoa, haholo-holo ho hloekisa lehlabathe kapa lisebelisoa tse ling tse pota-potileng lipheletsong. Ka ho etsa sena, nako ea bophelo ea bohale e ka lelefatsoa, hape e thibela li-shavings ho lahleloa ho batho ba kotsi.

3.3.4 Moralo oa Motheo:

Etsa bonnete ba hore liphaephe kapa li-fittings li tsitsitse ka nepo ho fumana tsela e nepahetseng. Ha o kopanya liphaephe, opareitara e lokela ho boloka sebaka se itseng mochining bakeng sa polokeho ea basebetsi.

Pele o tsamaisa, etsa bonnete ba hore li-clamp kaofela li tsitsitse hantle 'me li ke ke tsa oela nakong ea lipalangoang.

Latela matshwao ohle a polokeho ka hara mochini.

Litlhaloso

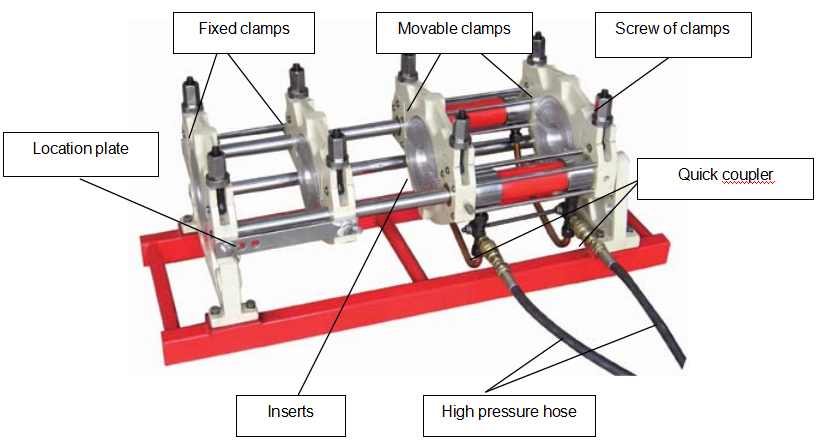

Mochine o na le foreimi ea motheo, hydraulic unit, heat plate, planing tool le tšehetso.

5.1 Foreimi

5.2 Sesebelisoa sa moralo le poleiti ea ho futhumatsa

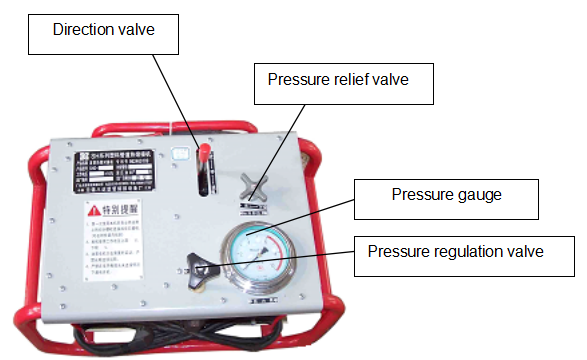

5.3 Yuniti ea Hydraulic

Taelo ea ho Sebelisa

6.1 Thepa eohle e lokela ho behoa sefofaneng se tsitsitseng le se omeletseng ho sebetsa.

6.2 Pele o sebetsa etsa bonnete ba lintho tse latelang:

u Mochini o maemong a matle

u Matla a lumellana le litlhoko ho latela mochini oa fusion ea butt

u Mohala oa motlakase ha o robehe kapa oa aparoa

u Lisebelisoa tsohle li tloaelehile

u Maqhubu a sesebelisoa sa ho rera a bohale

u Likarolo tsohle tse hlokahalang le lisebelisoa li teng

6.3 Khokahano le boitokiso

6.3.1 Hokela foreime ea mantlha ho hydraulic unit ka li-couplers tse potlakileng.

6.3.2 Hokela mohala oa poleiti ea ho futhumatsa ho lebokose la motlakase ka yuniti ea haeteroliki.

6.3.3 Hokela mohala oa poleiti ea ho futhumatsa le poleiti ea ho futhumatsa.

6.3.4 Kenya lisebelisoa tse loketseng ho foreimi ho latela bophara bo ka ntle ba liphaephe/li-fittings.

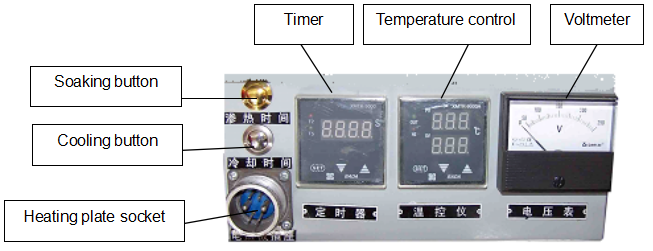

6.3.5 Ho ea ka litlhoko tsa ts'ebetso ea ho kenya le ho tjheseletsa, beha mocheso ho molaoli oa mocheso 'me u behe nako ka nako. (Sheba karolo ea 7 bukana ena).

6.4 Mehato ea ho cheselletsa

6.4.1 Lipeipi

Pele ho welding, pele, hlahloba hore na thepa le boemo ba eona ba khatello ke tsona tse hlokahalang. Taba ea bobeli, hlahloba hore na ho na le mengoo kapa maphao holim'a liphaephe / li-fittings. Haeba botebo ba mengopo kapa mapheo a ka holimo ho 10% ea botenya ba lerako, khaola karolo ea mapheo kapa mapheo. Hloekisa bokaholimo ba lipeipi ka lesela le hloekileng ho boloka lipheletso tsa lipeipi li hloekile.

6.4.2 Ho kokota

Beha liphaephe / li-fittings ka ho kenya foreimi 'me u boloke lipheletso tse lokelang ho ts'oaroa li be bolelele bo lekanang (ha ho na phello ho moralo le ho futhumatsa phala). Pipe e tsoang foreimi ea motheo e lokela ho tšehetsoa ho axial e bohareng ea li-clamps. Tlama li-screws tsa li-clamp ho lokisa liphaephe / li-fittings.

6.4.3 Fetola khatello

Bula ka ho feletseng valve ea taolo ea khatello ka ho feletseng, koala valve ea ho hlahloba ka thata ebe u sutumelletsa pele valve ea tataiso, u ntse u lokisa valve ea taolo ea khatello ho fihlela cylinder e qala ho tsamaea, nakong ena khatello ea tsamaiso ke khatello ea ho hula.

Bula valve ea taolo ea khatello ka ho feletseng, koala valve ea ho hlahloba ka thata ebe u sutumelletsa pele valve ea tataiso ho sa le joalo u fetole valve ea taolo ea khatello ho beha khatello ea tsamaiso e lekana le khatello ea ho hula e eketsa khatello ea butting.

6.4.4 Ho rera

Bula liphaephe/li-fittings ka mor'a hore u fetole chebahalo ea li-swing ho ea qetellong. Beha sesebelisoa sa ho rala lipakeng tsa lipeipi/li-fittings 'me u li bulele, koala liphaephe/li-fittings ka ho sebetsa holim'a valve ea tataiso, ha u ntse u fetola butle butle butle butle butle butle butle ho fihlela litelu li hlaha ka mahlakoreng ka bobeli. Fetola swing valve anti clockwise ho imolla khatello, ka mor'a nakoana bula foreimi, tima sesebelisoa sa ho rala 'me ue tlose.

Koala liphaephe / lipheletsong tse loketseng 'me u hlahlobe ho tsamaisana ha tsona. Phapang e kholo ha ea lokela ho feta 10% ea botenya ba lebota, 'me e ka ntlafatsoa ka ho lokolla kapa ho tiisa li-screws tsa li-clamps. Lekhalo pakeng tsa liphaephe tse peli ha lea lokela ho feta 10% ea botenya ba lerako; ho seng joalo lipeipi / li-fittings li lokela ho hlophisoa hape.

Tlhokomeliso: Botenya ba li-shavings bo lokela ho ba ka hare ho 0.2 ~ 0.5 mm mme bo ka fetoloa ka ho fetola bolelele ba lisebelisoa tsa lisebelisoa tsa moralo.

6.4.5 Ho futhumatsa

Hlakola lerōle kapa petso holim'a poleiti ea ho futhumatsa (Tlhokomeliso: U se ke ua senya PTFE layer holim'a poleiti ea ho futhumatsa.), 'me u netefatse hore mocheso o fihlile moo o hlokahalang.

Beha poleiti ea ho futhumatsa pakeng tsa liphaephe ka mor'a hore e fihle mocheso o hlokahalang. Koala liphaephe/li-fittings ka ho sebelisa valve ea tataiso 'me u phahamisetse khatello ho ea khatellong e boletsoeng ka ho sotha valve ea taolo ea khatello ho fihlela sefaha se fihla bophahamong bo boletsoeng.

Fetolela belofo ea ho chekoa ka tsela e khahlano le oache ho fokotsa khatello (eseng ho feta khatello ea ho hula) 'me u fetole valve ea swing ho ea qetellong.

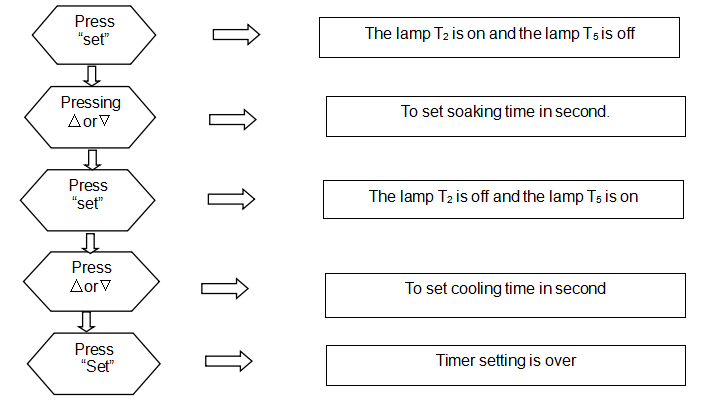

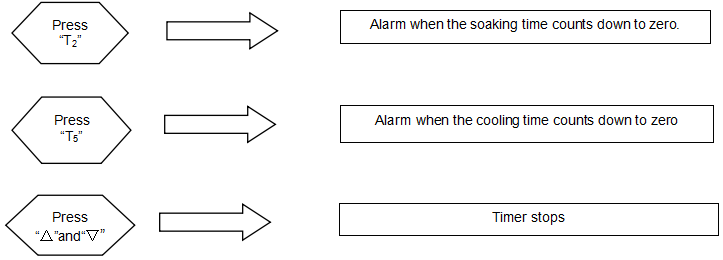

Tobetsa konopo "T2”, nako ea ho koloba e qala ho baloa mme nako e tla baloa ho fihlela ho zero ka motsotsoana, ebe molumo o tla buzz (bona karolo ea 7)

6.4.6 Ho kopanya le ho pholisa

Bula foreimi 'me u ntše poleiti ea ho futhumatsa ebe u koala likarolo tse peli tse qhibilihang kapele kamoo ho ka khonehang.

Boloka sebaka sa valve sebakeng se haufi bakeng sa metsotso ea 2 ~ 3, beha sebaka sa valve sebakeng se bohareng ebe u tobetsa konopo ("T5") ho bala nako ea ho pholile ho fihlela e felile. Ka nako ena, mochine o tla fana ka alamo hape. Fokotsa khatello, lokolla screw of clamps ebe o ntša liphaephe tse kopantsoeng.

Selaoli sa Nako le Mocheso

Haeba e 'ngoe ea li-parameter e fetoloa, e kang bophara ba ka ntle, SDR kapa thepa ea liphaephe, nako ea ho noa le nako ea ho pholile e lokela ho tsosolosoa ho ea ka mokhoa oa ho tjheseletsa.

7.1 Tlhophiso ea nako

7.2 Taelo ea Tšebeliso

7.3 Tlhophiso ea taolo ea mocheso

1) Tobetsa "SET" bakeng sa metsotsoana e fetang 3 ho fihlela "sd" e bontšoa fensetereng e ka holimo

2) Tobetsa "∧" kapa "∨" ho fetola boleng ho bo boletsoeng (tobetsa "∧" kapa "∨" u sa khaotse, boleng bo tla eketsa kapa bo tlose ka bohona)

3) Kamora ho beha, tobetsa "SET" ho khutlela ho sehokelo sa ho beha leihlo le ho laola

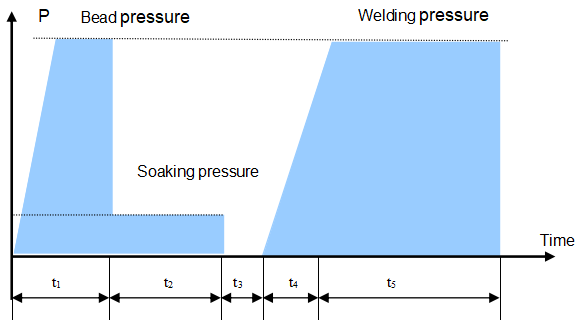

Reference of Welding Standard (DVS2207-1-1995)

8.1 Ka lebaka la phapang pakeng tsa litekanyetso tsa welding le lisebelisoa tsa PE, nako le khatello li fapana ka mekhahlelo e fapaneng ea welding. E fana ka maikutlo a hore li-parameter tsa sebele tsa welding li lokela ho fanoa ke baetsi ba liphaephe le li-fittings.

8.2 Fuoa tjheseletsa mocheso oa liphaephe entsoe ho tloha PE, PP le PVDF ka DVS maemo a ranges ho tloha180 ℃ ho 270 ℃. Mocheso oa kopo ea poleiti ea ho futhumatsa o ka hare ho 180℃230℃, le boholo ba eona. mocheso holim'a metsi o ka fihla ho 270 ℃.

8.3 Reference standard DVS2207-1-1995

| Botenya ba lebota (mm) | Bolelele ba lifaha (mm) | Khatello ea ho haha lifaha (MPa) | Nako ea ho noa t2(metsotsoana) | Khatello ea metsi (MPa) | Ho fetoha ha nako t3(metsotsoana) | Nako ea ho eketsa khatello t4(metsotsoana) | Khatello ea welding (MPa) | Nako ea ho pholisa t5(mets) |

| 0 - 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5-7 | 1.0 | 0.15 | 45-70 | ≤0.02 | 5 - 6 | 5 - 6 | 0.15±0.01 | 6-10 |

| 7-12 | 1.5 | 0.15 | 70-120 | ≤0.02 | 6 - 8 | 6 - 8 | 0.15±0.01 | 10-16 |

| 12-19 | 2.0 | 0.15 | 120-190 | ≤0.02 | 8-10 | 8-11 | 0.15±0.01 | 16-24 |

| 19-26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10-12 | 11-14 | 0.15±0.01 | 24-32 |

| 26-37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12-16 | 14-19 | 0.15±0.01 | 32-45 |

| 37-50 | 3.5 | 0.15 | 370 ~ 500 | ≤0.02 | 16-20 | 19-25 | 0.15±0.01 | 45-60 |

| 50-70 | 4.0 | 0.15 | 500 ~ 700 | ≤0.02 | 20-25 | 25-35 | 0.15±0.01 | 60-80 |

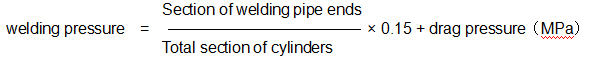

Tlhokomeliso: Khatello ea ho haha lifaha le khatello ea welding ka sebopeho ke khatello e khothaletsoang ea sebopeho, khatello ea gauge e lokela ho baloa ka foromo e latelang.

Litlhaloso:

Litlhahlobo le Litharollo Tse Hloekileng

8.1 Mathata a khafetsa a boleng ba manonyeletso a sekaseka:

8.2 Linako tsa tlhokomelo le tlhahlobo

8.2.1 Tlhokomelo

※ Ho roala poleiti ea ho futhumatsa

Ka kopo ela hloko ho sebetsana le poleiti ea ho futhumatsa. Boloka sebaka se itseng hole le poleiti ea ho futhumatsa. Ho hloekisoa ha bokaholimo ba eona ho tlameha ho etsoa ka holim'a metsi ho ntse ho futhumetse ka ho sebelisa lesela le bonolo kapa pampiri, ho qoba lisebelisoa tse senyang tse ka senyang seaparo.

Ka linako tse ling hlahloba ka tsela e latelang

1) Hloekisa bokaholimo ka ho sebelisa sesepa se potlakileng sa mouoane (joala)

2) Sheba ho tiisa ha li-screws le cable le boemo ba plug

3) Netefatsa mocheso oa eona o holim'a metsi ka ho sebelisa scanning ea infrared-ray

※ Sesebelisoa sa ho rala

Ho khothaletsoa ka matla ho boloka li-blades kamehla li hloekile le ho hlatsoa li-pulleys ka ho sebelisa sesepa. Nako le nako, etsa ts'ebetso e felletseng ea ho hloekisa.

※ yuniti ea Hydraulic

E boloke ka tsela e latelang

1) Lekola boemo ba oli nako le nako

2) Tlosa oli ka botlalo likhoeling tse ling le tse ling tse 6

3) Boloka tanka le potoloho ea oli e hloekile

8.2.2 Tlhokomelo & Tlhahlobo

Tlhahlobo e tloaelehileng

| Ntho | Tlhaloso | Hlahloba pele o sebelisoa | Ea pele khoeli | Likhoeli tse ling le tse ling tse 6 | Emong le emong selemo |

| Sesebelisoa sa ho rera | Ho sila kapa ho khutlisa lehare Tlosa thapo haeba e robehile Matlafatsa likhokahano tsa mochini hape |

● ● |

● |

| ● ●

|

| Letlapa le futhumatsang | E kopane hape le thapo le sokete Hloekisa holim'a poleiti e futhumatsang, koahela PTFE lera hape ha ho hlokahala Matlafatsa likhokahano tsa mochini hape | ● ●

● |

● |

|

●

|

| Temp. tsamaiso ea taolo | Hlahloba sesupo sa mocheso Tlosa thapo haeba e robehile |

● |

|

| ● ● |

| Sistimi ea Hydraulic | Checkout khatello ea mali Fetola litiiso haeba hydraulic unit e dutla Hloekisa sefe Etsa bonnete ba hore oli e lekane bakeng sa ts'ebetso Fetola oli ea hydraulic Kenya sebaka haeba hose ea oli e robehile |

● ● ● |

|

● | ● ●

● ●

|

| Motheo Foreimi | Tiisa li-screws qetellong ea axis ea foreimi Fafatsa pente ea antirust hape ha ho hlokahala | ●

| ●

| ●

|

● |

| Matla Phepelo | Tobetsa konopo ea teko ea mosireletsi oa potoloho ho etsa bonnete ba hore e ka sebetsa ka mokhoa o tloaelehileng Tlosa thapo haeba e robehile | ●

● |

|

● |

|

“●”………… nako ea tlhokomelo

9.3 Litlhahlobo le tharollo tse sa sebetseng khafetsa

Nakong ea ts'ebeliso, li-hydraulic unit le li-unit tsa motlakase li ka hlaha mathata a mang. Ho se sebetse hantle hangata ho thathamisitsoe ka tsela e latelang:

Ka kopo sebelisa lisebelisoa tse khomaretsoeng, likarolo tse ling kapa lisebelisoa tse ling tse nang le setifikeiti sa polokeho ha u ntse u lokisa kapa u fetola likarolo. Lisebelisoa le likarolo tse ling tse se nang setifikeiti sa polokeho li thibetsoe ho sebelisoa.

| Ho se sebetse hantle ha hydraulic unit | |||

| No | ha e sebetse hantle | ho se sebetse hantle ditshekatsheko | Litharollo |

| 1 | Mochine oa pompo ha o sebetse |

| |

| 2 | Enjene ea pompo e potoloha butle haholo ka lerata le sa tloaelehang |

| 1. Etsa bonnete ba hore mojaro oa enjene o ka tlase ho 3 MPa 2. Lokisa kapa u nke sebaka sa pompo 3. Hloekisa sefe 4. Sheba ho se tsitse ha matla |

| 3 | Silinda e sebetsa ka mokhoa o sa tloaelehang |

| |

| 4 | Moqomo o lutla | 1. Lesale la oli le na le phoso 2. Silinda kapa piston e senyehile hampe | 1. Kenya sebaka sa lesale la oli 2. Kenya sebaka sa silinda |

| 5 | Khatello e ke ke ea eketseha kapa ho feto-fetoha ha maemo ho hoholo haholo | 1. Motheo oa valve ea ho phalla o koetsoe. 2. Pompo e dutla. 3. Motsoako o kopantsoeng oa pompo o lokolotsoe kapa groove ea bohlokoa ke skid. 4. Sephahla sa khatello ea khatello ha sea koaloa | 1. Hloekisa kapa u nke sebaka sa mantlha sa valve e phallang haholo 2. Kenya sebaka sa pompo 3. Beha sebaka sa lenonyello slack 4. Notlela belofo |

|

Ho se sebetse hantle ha likarolo tsa motlakase | |||

| 1 | Mochine ha o sebetse |

| 1. Sheba thapo ea matla 2. Sheba matla a ho sebetsa 3. Bula fault fault interrupter |

| 2 | Maeto a ho fetola liphoso tsa fatše |

| 1. Sheba lithapo tsa motlakase 2. Sheba likarolo tsa motlakase. 3. Lekola sesebelisoa sa polokeho ea matla a holimo holimo |

| 3 | Mocheso o sa tloaelehang oa eketseha | 1. Sesebelisoa sa taolo ea mocheso se bulehile 2. Sensor (pt100) ha e tloaelehe. Boleng ba ho hanyetsa ba4 le 5 ba sokete ea poleiti ea ho futhumatsa e lokela ho ba ka hare ho 100 ~ 183Ω 3. Thupa e futhumatsang ka har'a poleiti ea ho futhumatsa ha e tloaelehe. Ho hanyetsa pakeng tsa 2 le 3 e lokela ho ba ka hare ho23Ω. Ho hanyetsa mocheso pakeng tsa hlooho ea molamu oa ho futhumatsa le khetla e ka ntle e tlameha ho ba ho feta 1MΩ 4. Na ho baloa ha mocheso oa mocheso ho feta 300 ℃, e leng se fanang ka maikutlo a hore sensor ea hae e ka senyeha kapa khokahanyo ea theoha. Na molaoli oa mocheso o lokela ho bontša LL, e leng se bontšang hore sensor e na le potoloho e khutšoanyane. Haeba molaoli oa mocheso o lokela ho bonts'a HH, e fanang ka maikutlo a hore potoloho ea sensor e bulehile. 5. Lokisa mocheso ka konopo e teng ho molaoli oa mocheso.

| 1. Hlahloba kgokelo ya contactors 2. Kenya sebaka sa sensor

3. Beha sejana se futhumatsang sebaka

4. Kenya sebaka sa taolo ea mocheso

5. Sheba mekhoa ea ho beha mocheso 6. Hlahloba le sebaka sa contactors haeba ho hlokahala |

| 4 | Ho lahleheloa ke taolo ha ho futhumatsa | Leseli le khubelu lea khanya, empa mocheso o ntse o nyoloha, ke hobane sehokelo se na le phoso kapa manonyeletso a 7 le a 8 ha a khone ho bula ha a fumana mocheso o hlokahalang. | Kenya sebaka sa taolo ea mocheso

|

| 5 | Sesebelisoa sa ho rera ha se potoloha | Moeli oa switjha ha o sebetse kapa likarolo tsa mochini tsa sesebelisoa sa ho rala li koetsoe. | Fetola sesebelisoa sa moeli oa sesebelisoa kapa sprocket e nyane |