SDY630/400 BUTT FUSION MACHINE MANUAL OPERATIONS

Tlhaloso e Ikgethileng

Re khothaletsa ho bala mongolo oohle ka hloko ho netefatsa polokeho ea opareitara le lisebelisoa pele o qala ho sebelisa mochini. Bukana ena ea ts'ebetso e lokela ho bolokoa ka hloko hore e sebelisoe nakong e tlang.

3.1 Thepa ena ha e tšoanelehe bakeng sa ho se hlalose lipeipi tsa thepa; ho seng joalo e ka senya kapa ea etsahala kotsi.

3.2 Se ke oa sebelisa mochini sebakeng sa kotsi ea ho phatloha.

3.3 Mochine o tlameha ho sebelisoa ke setsebi sa mosebetsi.

3.4 Mochini o lokela ho sebetsoa sebakeng se omileng. Mehato ea ts'ireletso e lokela ho nkuoa ha e sebelisoa pula kapa mobung o mongobo.

3.5 Matla a ho kenya ke 380V±10%, 50Hz. Haeba ho sebelisoa mola oa ho atolosa, mohala o tlameha ho ba le karolo e lekaneng ea ho etella pele.

Tlhaloso ea likarolo

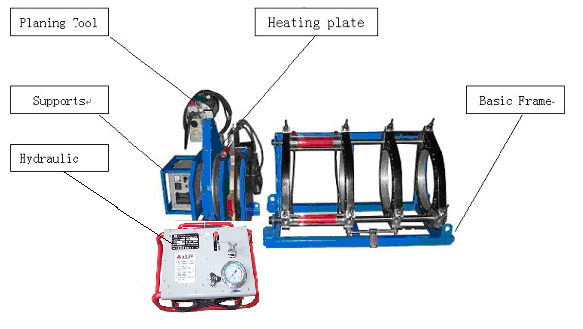

Mochine o thehoa ho tloha foreimi ea motheo, hydraulic unit, futhumatsang poleiti, sesebelisoa sa ho rera, tšehetso ea sesebelisoa sa ho rala le lebokose la motlakase.

3.1 tlhophiso ea mochini

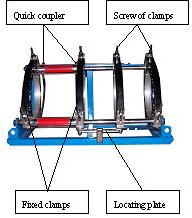

3.2 Foreimi ea motheo

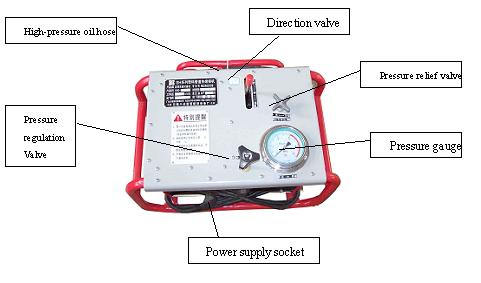

3.3 li-hydraulic units

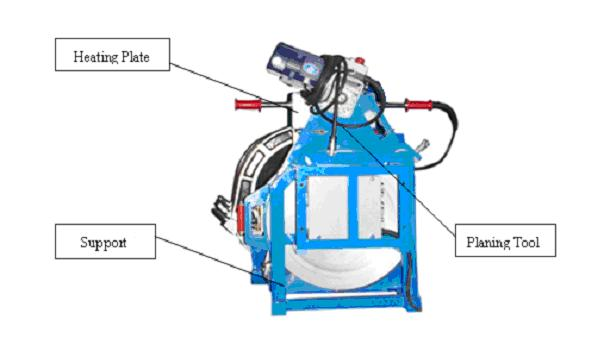

3.4 Sesebelisoa sa ho rala le poleiti ea ho futhumatsa

Taelo ea ho sebelisoa

4.1 Likarolo tsohle tsa lisebelisoa li lokela ho behoa sefofaneng se tsitsitseng le se omeletseng ho sebetsa.

4.2 Etsa bonnete ba hore matla ho latela mochini oa fusion oa butt o kopiloeng, mochini o maemong a matle, mohala oa motlakase ha o robehe, lisebelisoa tsohle li tloaelehile, mahare a sesebelisoa sa ho rala a bohale, likarolo tsohle tse hlokahalang le lisebelisoa li felile.

4.3 Khokahano ea Hydraulic le ea motlakase

4.3.1 hokela foreime ea motheo le hydraulic unit by quick coupler.

4.3.2 hokela mohala oa poleiti ea ho futhumatsa le lebokose la motlakase ka foreimi ea motheo.

4.3.3 hokela mohala oa poleiti ea ho futhumatsa le poleiti ea ho futhumatsa.

4.3.4 Kenya lintho tse kentsoeng ho latela bophara ba phala / ho lekana le foreimi ea mantlha.

4.4 Mokhoa oa ho cheselletsa

4.4.1 Sheba bophara le botenya ba lebota kapa SDR ea lipeipi/li-fittings tse lokelang ho chesetsoa li nepahetse. Sebaka sa eona se tlameha ho hlahlojoa pele se qala ho cheselletsa, haeba mongoapo o feta 10% ea botenya ba lebota, e tlameha ho ba sehiloeng se leeme ho se sebelisa.

4.4.2 Hloekisa bokaholimo ba lipeipi bo ka hare le bo kantle hore bo chesetsoe.

4.4.3 Beha liphaephe/li-fittings ka har'a foreime, bolelele ba liphaephe/li-fittings li lokela ho ts'oaroa ho tsoa ka ntle mohlomong li ts'oana (tse khuts'oane ka moo ho ka khonehang). Qetello e 'ngoe ea phala e lokela ho tšehetsoa ke lirolara ho fokotsa khohlano. Ebe u fafatsa screw ea li-clamps ho tšoara lipeipi/ho kenya.

5.4.4 Beha sesebelisoa sa ho rala ka har'a foreimi pakeng tsa lipeipi / li-fittings le ho bulela, koala liphaephe / li-fittings ka mokhoa oa ho sebetsa oa valve ea hydraulic unit ho fihlela ho na le li-shavings tse tsoelang pele li hlahile mahlakoreng ka bobeli.(khatello ea ho kuta ka tlase ho 2.0 Mpa). Beha thipa ea li-valve sebakeng se bohareng 'me u boloke metsotsoana e seng mekae, ebe u bula foreimi, tima sesebelisoa sa ho rala ebe u se ntša ka foreimi. Botenya ba li-shavings bo lokela ho ba 0.2 ~ 0.5 mm mme bo ka fetoloa ka ho fetola bolelele ba lisebelisoa tsa lisebelisoa.

4.4.5 Koala liphaephe/lipheletso tsa ho kenya 'me u hlahlobe ho se tsamaisane hantle ha tsona. The max. Ho se tsamaisane hantle ha hoa lokela ho feta 10% ea botenya ba lebota, e ka ntlafatsoa ka ho lokisa tekano ea liphaephe le ho lokolla kapa ho tiisa li-screws tsa li-clamps. Lekhalo pakeng tsa liphaephe tse peli ha lea lokela ho feta 10% ea botenya ba lebota, kapa le lokela ho khaoloa hape.

4.4.6 Hlakola lerōle 'me u lule holim'a poleiti ea ho futhumatsa (U se ke ua ngwapa PTFE layer holim'a poleiti ea ho futhumatsa).

4.4.7 Beha poleiti ea ho futhumatsa ka har'a foreimi pakeng tsa lipeipi ka mor'a hore mocheso o hlokahalang o fihle. Phahamisa khatello ho fihlela moo e hlokahalang ho fihlela sefaha se fihla bophahamong bo nepahetseng.

4.4.8 Fokotsa khatello ho boleng bo lekaneng ho boloka lipheletsong tse peli tsa liphaephe/li-fittings li hokahane le poleiti ea ho futhumatsa bakeng sa nako ea ho koloba e hlokahalang.

4.4.9 Ha nako e fihlile, bula foreime 'me u ntše poleiti ea ho futhumatsa, koala likarolo tse peli tse qhibilihisang kapele kamoo ho ka khonehang.

4.4.10 Eketsa khatello ho fihlela khatello ea welding 'me u boloke lenonyeletso ho fihlela nako ea ho pholisa. Fokotsa khatello, lokolla screw of clamps 'me u ntše phala e kopantsoeng.

Sesebelisoa sa Nako

Haeba e 'ngoe ea paramente e fetoloa, joalo ka bophara ba SDR kapa thepa ea phala, soak ka nako ea ho futhumatsa le nako ea ho futhumatsa e lokela ho hlophisoa ho latela maemo a tjheseletsa.

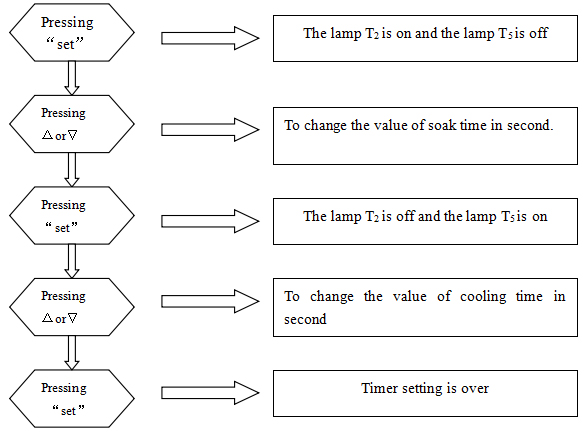

6.1 Tlhophiso ea nako

6.2 Taelo ea Tšebeliso

Welding standard le hlahloba

7.1 Ka lebaka la maemo a fapaneng a welding le lisebelisoa tsa PE, nako le khatello ea mohato oa ts'ebetso ea butt fusion e fapane. E fana ka maikutlo a hore liphaephe li lokela ho paka hore na li-parameter tsa welding le li-fittings li etsoa joang.

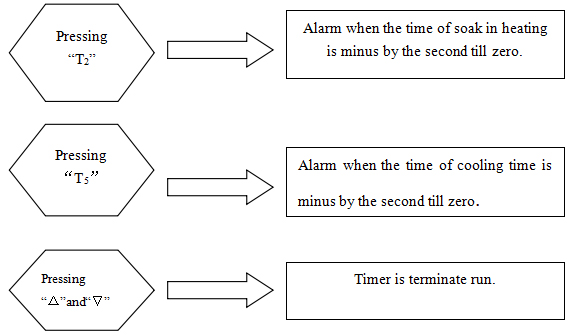

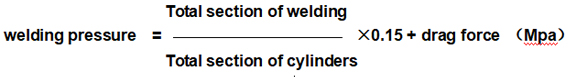

7.2 Tekanyetso ea litšupisoDVS2207-1-1995

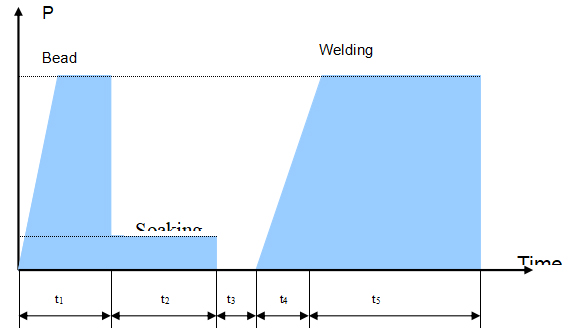

| Botenya ba lebota (mm) | Bolelele ba lifaha (mm) | Khatello ea lifaha (Mpa) | Nako ea ho noa t2(Motsotsoana) | Khatello ea metsi (Mpa) | Ho fetoha ha nako t3(Motsotsoana) | Nako ea ho phahama t4(Motsotsoana) | Khatello ea welding (Mpa) | Nako ea ho pholisa t5(mets) |

| 0 - 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5-7 | 1.0 | 0.15 | 45-70 | ≤0.02 | 5 - 6 | 5 - 6 | 0.15±0.01 | 6-10 |

| 7-12 | 1.5 | 0.15 | 70-120 | ≤0.02 | 6 - 8 | 6 - 8 | 0.15±0.01 | 10-16 |

| 12-19 | 2.0 | 0.15 | 120-190 | ≤0.02 | 8-10 | 8-11 | 0.15±0.01 | 16-24 |

| 19-26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10-12 | 11-14 | 0.15±0.01 | 24-32 |

| 26-37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12-16 | 14-19 | 0.15±0.01 | 32-45 |

| 37-50 | 3.5 | 0.15 | 370 ~ 500 | ≤0.02 | 16-20 | 19-25 | 0.15±0.01 | 45-60 |

| 50-70 | 4.0 | 0.15 | 500 ~ 700 | ≤0.02 | 20-25 | 25-35 | 0.15±0.01 | 60-80 |

Ela hloko:

Litlhaloso:

Ts'ebetso ea papatso ea polokeho

Ho khothaletsoa ka matla ho bala le ho latela ka hloko melao e latelang e bolokehileng pele o sebelisa mochini.

8.1 Basebelisi ba litsebo ba tlameha ho ikoetlisa pele ba sebelisa le ho sebelisa mochini.

8.2 Mochini o lokela ho hlahloba le ho lokisa le ho sebelisa lilemo tse peli tse fetileng bakeng sa lehlakoreng le sireletsehileng.

8.3 Matla: Polaka ea phepelo ea motlakase e fanoa ka molao oa polokeho bakeng sa basebelisi ba litsebo le polokeho ea mochini.

Sebaka se sireletsehileng se tlameha ho ba le lentsoe kapa setšoantšo e le hore se khetholle.

Hokela le mochini le matla: Matla a ho kenya ke 380±20V ea 50Hz. Haeba ho sebelisoa mola oa ho atolosa, mohala o tlameha ho ba le karolo e lekaneng ea ho etella pele.

Grounding: E tlameha ho ba le lets'oao le fetisang la mohala sebakeng sa moaho, khanyetso e nang le motheo ke sutu ea tšireletso le ho netefatsa hore ha e fete 25 voltage le ho beha kapa ho hlahlojoa ke setsebi sa motlakase.

Polokelo ea Motlakase: Mochini o tlameha ho sebelisa polokelo hantle ho netefatsa polokeho.

Connect le mochine lokela ho buisana le sebetsa molao.

※ Qoba kotsi ea mofuta ofe kapa ofe e bakoang ke motlakase.

※ Qoba ho khaola phepelo ea motlakase ka ho hula

※ Qoba ho sisinyeha, hula le ho emisa mochini ka mohala oa mohala.

※ Qoba moeli le boima ba mohala oa mohala, mocheso oa mohala ha oa lokela ho feta 70℃.

※ Mochine o lokela ho sebetsoa sebakeng se omileng. Mehato ea ts'ireletso e lokela ho nkuoa ha e sebelisoa pula kapa mobung o mongobo.

※ Sebaka sa ho sebetsa se tlameha ho hloeka.

※ Mochine o lokela ho hlahlojoa le ho lokisa nako.

※ Nako le nako mohala oa mohala oa insulation o lokela ho hlahloba le ho o hatella ka ho khetheha

※ Ho kotsi haholo ho sebelisa mochine ha ho na pula kapa maemong a koro.

※ Sekhechana sa potoloho se sebelisoang hona joale se lokela ho lokisoa ka khoeli.

※ Motlakase o lokela ho hlahloba motheo oa boemo.

※ Ha u hloekisa mochine ka hloko, u se ke ua senya li-insulated tsa mochine kapa ua sebelisa benzine, impregnant joalo-joalo.

※ Mochini o lokela ho bolokoa ka har'a maemo a deiccation.

※ Li-plug tsohle li tlameha ho tsoa mohloling oa motlakase.

※ Tšebeliso ea mechine e fetileng, mochine o lokela ho lula o le maemong a sebetsang hantle.

E fana ka maikutlo a ho bala le ho latela melao ka hloko pele o sebelisa mochini.

Kotsi ea ho qala: pele mochini o sebelisoa, polaka ea phepelo ea motlakase e fanoa ka polokeho.

Liphaephe tse behiloeng ka har'a mochini:

Beha liphaephe ka har'a li-clamps le ho li fasten, sebaka sa liphaephe tse peli tse qetellang li lokela ho kenya sesebelisoa sa moralo le ts'ebetso ea inshorense, ho qoba kotsi ea mofuta ofe kapa ofe e bakoang ke motlakase le ho sebetsa.

Ho sebetsa ha maemo:

Sebaka sa ho sebetsa se tlameha ho hloeka, se omelle 'me se bonese hantle.

Ho kotsi haholo ho sebelisa mochini ha pula e na kapa maemong a koro kapa haufi le maro a tukang.

Hlokomela hore batho bohle ba haufi le mochini ba hole le polokeho.

Liaparo:

Boloka tlhokomelo e phahameng ha u ntse u sebelisa mochini ka lebaka la mocheso o phahameng o amehang holim'a poleiti ea ho futhumatsa e lula e feta 200 ℃, ho khothaletsoa ka matla ho sebelisa liatlana tse loketseng. Qoba liaparo tse telele 'me u qobe lipetja, lipetja tse ka' nang tsa hokelloa mochining.

Ela hloko kotsi 'me u thibele likotsi

Mochini oa ho kopanya butt:

Tšebeliso ea mochine e tlameha ho etsoa ka mokhoa o nepahetseng.

※ Letlapa le futhumatsang

Plate e futhumatsang ka lebaka la mocheso o phahameng o fetang 270 ℃, ho khothaletsoa ho nka mehato:

---sebelisa liatlana tse nang le mocheso o phahameng

---kamora phala e kopanyang butt le phaephe, poleiti e futhumatsang e tlameha ho kenngoa.

--- e phethiloe poleiti ea ho futhumatsa e tlameha ho beoa lebokoseng.

---e dumellwa hore e se ke ya ama poleiti e futhumatsang.

※ Sesebelisoa sa ho rala

---pele ho ts'ebetso ea Scraping, liphaephe le fatše ho qoba ho silafatsa lipeipi tse shebaneng li fela.

--- e phethile sesebelisoa sa ho rala e tlameha ho beoa ho Support bakeng sa sesebelisoa sa ho rala le poleiti ea ho futhumatsa

※ Foreimi ea motheo

---o ile a qala esale pele hore foreime ea motheo ka ho boletsoe ka holimo ho bokana It' a loketse bakeng sa mefuta eohle ea phala ho tjheseletsa phala.

---Ha o qala ho sebetsa hlokomela ho qoba maoto kapa matsoho a suthang. Ke ntho e tlamang ho ba hole le foreimi ea motheo.

--- hlokomela hore batho bohle ba potileng mochini ba hole le polokeho.

---Basebelisi ba litsebo ba tlameha ho boloka melao ea polokeho.

Tlhokomelo

| Ntho | Tlhaloso | Hlahloba pele o sebelisoa | Khoeli ea pele | Likhoeli tse ling le tse ling tse 6 | Selemo le selemo |

| Sesebelisoa sa ho rera | Fetola lehare kapa o hlatsoe hape Sheba hore na thapo e robehile Sheba hore na khokahano ea mochini e theohile |

●

|

● |

| ● ●

|

| Letlapa le futhumatsang | Sheba lithapo le li-socket joints Hloekisa holim'a poleiti e futhumatsang, koahela PTFE lera hape ha ho hlokahala Sheba hore na khokahano ea mochini e theohile | ● ●

|

● |

|

●

|

| Sistimi ea taolo ea mocheso | Hlahloba sesupo sa mocheso Sheba hore na thapo e robehile |

● |

|

| ● ● |

| Sistimi ea Hydraulic | Checkout khatello ea mali Ho hlahloba hore motsoako oa lipeipi tsa oli ha oa lutla, oa tiisa hape kapa oa nkeloa sebaka Hloekisa sefe Sheba oli haeba e haella Fetola oli Sheba hore na hose ea oli e robehile |

●

●

● |

|

●

| ●

● ●

|

| Motheo Foreimi | Sheba hore na sekoti se tiisitsoeng se qetellong ea axis ea foreimi se ne se hlephile Fafatsa pente ea antirust hape ha ho hlokahala |

●

|

●

|

●

|

● |

| Matla Phepelo | Tobetsa konopo ea teko ea mosireletsi oa potoloho ho bona hore mosireletsi oa potoloho o sebetsa ka mokhoa o tloaelehileng Sheba hore na thapo e robehile | ● ● |

|

● |

|