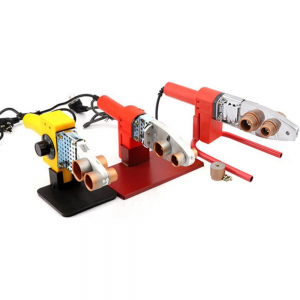

T2S160 Hand-push Pipe Welder

Lisebelisoa le likarolo

★E loketse bakeng sa ho hokela PE, PP, phala ea PVDF le phaephe, lipeipi le liphaephe tse kenyang setšeng sa kaho le foro, hape e ka sebelisoa thupelong;

★ E na le rack, mochini oa ho sila, poleiti e ikemetseng ea ho futhumatsa, sekhetla sa ho sila le borakete ea lipoleiti tsa ho futhumatsa;

★Letlapa la ho futhumatsa le amohela mokhoa o ikemetseng oa ho laola mocheso le PTFE holim'a ho roala;

★ mochini oa ho sila ka motlakase;

★ Karolo e ka sehloohong ea foreimi e entsoe ka lisebelisoa tsa aluminium alloy, tse bonolo ka sebopeho, li kopane ebile li bonolo ho li sebelisa.

Litlhaloso

| 1 | Lebitso la thepa le mohlala | T2S-160/50 tjheseletsa butt ka letsoho | |||

| 2 | Liphaephe tse chesehang (mm) | Ф160, Ф140, Ф125, Ф110, Ф90, Ф75, Ф63,Ф50 | |||

| 3 | Ho kheloha ha docking | ≤0.3 limilimithara | |||

| 4 | Phoso ea mocheso | ±3℃ | |||

| 5 | Kakaretso ea tšebeliso ea matla | 1.7KW/220V | |||

| 6 | Mocheso oa ho sebetsa | 220 ℃ | |||

| 7 | Mocheso oa tikoloho | -5 - +40 ℃ | |||

| 8 | Nako e hlokahalang ho fihlela mocheso oa welder | < 20mins | |||

| 9 | Mocheso o moholo oa ho futhumatsa poleiti | 270 ℃ | |||

| 10 | Boholo ba sephutheloana | 1, rack (ho kenyeletsoa le thepa ea ka hare), baskete (ho kenyeletsoa le sehaho sa milling, poleiti e chesang) | 55*47*52 | Net boima ba 32KG | Kakaretso ea boima ba 37KG |

Taolo ea boleng

1) Pele taelo e ka tiisoa qetellong, re ne re tla hlahloba ka tieo thepa, 'mala, boholo ba mohlala ka mohato.

2) Re morekisi, hape joalo ka molateli oa taelo, re ne re ka latela mohato o mong le o mong oa tlhahiso ho tloha qalong.

3) Re na le sehlopha sa QC, sehlahisoa se seng le se seng se ne se tla hlahlojoa ke bona pele se tletse

4) Re tla leka ka hohle ho thusa bareki ho rarolla mathata ha a etsahala.

Melemo ea rona

1. Lilemo tse 10 boiphihlelo ba ho etsa mochini oa welding

2. Tsamaiso ea "8S" ke motheo oa tšebeletso e ntle ka ho fetisisa.

3. Baenjiniere ba fetang 80 ba boloka matla a R & D a matla, a ka kopana le kopo ea tekheniki ho tsoa ho moreki.

4. Re ikemiselitse ho fana ka tharollo litlhoko tsa bareki ba rona, le ho fana ka tsa morao-rao tsa theknoloji, le ho ikemisetsa ho rarolla mathata a bareki.

Re amohela bareki ba tsoang lefats'eng lohle bakeng sa ho botsa le ho reka.