Bokamoso ba ho Cheselletsa Liphaephe: Mechini ea ho Welding ea Phaephe e Ikemetseng e Phahameng ka ho Fetisisa

Kenyelletso ea Mechini ea ho Welding ea Liphaephe tsa Plastiki e sebetsang ka katleho e phahameng

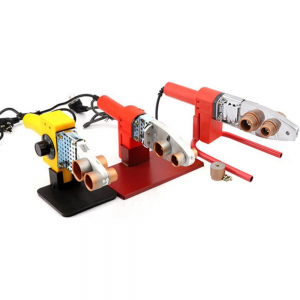

Mechini ea tjheseletsa ea liphaephe tsa polasetiki e sebetsang hantle haholo e emela sehlohlolong sa theknoloji ea tjheseletsa, e etselitsoeng ho kopanya liphaephe tsa polasetiki ka lebelo le ikhethang le ho nepahala. Ho kenyelletsa litaolo tsa morao-rao, mechini ena e laola ka nepo linako tsa ho futhumatsa, ho pholisa le ho kopanya, ho ikamahanya le lisebelisoa tse fapaneng tsa liphaephe le li-diameter ho fana ka liphetho tse nepahetseng tsa welding. E loketse merero e meholo le lits'ebetso tse hlokang indasteri, li fana ka ts'ebetso e se nang moeli, e sebetsang hantle e fokotsang nako ea merero haholo.

Lintlha tsa Bohlokoa le Melemo

●Automated Precision:Lenaneo le tsoetseng pele le netefatsa hore weld e 'ngoe le e' ngoe e etsoa tlas'a maemo a nepahetseng, ho fokotsa monyetla oa phoso ea motho le litšila tsa thepa.

●Lebelo le Tlhahiso: Ka lipotoloho tse potlakileng tsa ho futhumatsa le ho pholisa, mechini ena e ka tlatsa li-welds ka nako e itseng e hlokoang ke mekhoa ea matsoho, e eketsa haholo tlhahiso ea morero.

●Ho feto-fetoha ha maemo: E khona ho sebetsana le mefuta e mengata ea boholo ba liphaephe le mefuta, li hlomelloa bakeng sa likopo tse fapaneng, ho tloha tsamaisong ea metsi ho ea ho likhoele tsa ho tsamaisa lik'hemik'hale.

●Ho Rengoa ha Lintlha le Taolo ea Boleng: Ts'ebetso e kopaneng ea tlhahlobo le ho rekota e thusa ho lekola nako ea nnete le tlhahlobo ea nalane ea boleng ba weld, ho netefatsa hore ho latela litekanyetso tse thata.

Lisebelisoa

Ho feto-fetoha ha maemo le ts'ebetso e phahameng ea mechini ena ea li-welding e etsa hore e be ea bohlokoa haholo makaleng a fapaneng, ho kenyelletsa:

●Meralo ea motheo ea metsi le likhoerekhoere: Bakeng sa ho aha marang-rang a matla, a sa luleng a bohlokoa bakeng sa nts'etsopele ea litoropo ea sejoale-joale.

●Mekhoa ea Kabo ea Khase: Ho netefatsa lithapo tsa phepelo ea khase tse bolokehileng le tse tšepahalang tse nang le li-welds tsa boleng bo holimo.

●Indasteri Process Piping: Ho fihlela litlhoko tse matla tsa indasteri ea lik'hemik'hale, ea meriana le ea ho lokisa lijo ka liphaephe tse cheselitsoeng ka nepo.

●Meepo le Ts'ebetso ea Offshore: Ho fana ka litharollo tsa nako e telele bakeng sa maemo a phephetsang ao re kopanang le 'ona molemong oa ho rala lisebelisoa le tikoloho ea maoatleng.

Ho Khetha Mochini oa ho Welding oa Phaephe ea Plastiki o Nepahetseng ka Matla a Phahameng

Ha u khetha mochini o tjheseletsang lipeipi tsa polasetiki tse sebetsang hantle haholo, nahana ka lintlha tse latelang ho netefatsa hore o tsetela tharollong e fihlelang litlhoko tsa hau tse ikhethileng:

●Bokhoni le Kamano: Lekola boholo ba bophara ba liphaephe le lisebelisoa tseo mochini o ka li amohelang ho netefatsa hore li lumellana le litlhoko tsa projeke ea hau.

●Sehokelo sa Mosebelisi le Bonolo ba Tšebeliso: Khetha mechini e nang le likhokahano tse hlakileng le ts'ebetso e bonolo ea basebelisi ho fokotsa nako ea koetliso le ho ntlafatsa phallo ea mosebetsi.

●Portability le Durability: Nahana ka motsamao oa mochini bakeng sa lits'ebetso tsa setšeng le boleng ba eona ba ho aha bakeng sa ho mamella maemo a boima.

●Tšehetso le Tlhokomelo: Lekola lits'ebeletso tsa tšehetso tsa moetsi le ho fumaneha ha likarolo tse ling ho netefatsa ts'epo le ts'ebetso ea nako e telele.

Malebela a ho Eketsa Tšebeliso e Ntle

●Koetliso ea Basebetsi: Tsetela ho koetliso e felletseng bakeng sa basebelisi ho sebelisa bokhoni ba mochini ka botlalo le ho ntlafatsa ts'ebetso ea ho cheselletsa.

●Tlhokomelo e Thibelang: Khomarela kemiso ea kamehla ea tlhokomelo ho boloka ts'ebetso e phahameng le ho thibela nako ea ho theoha.

●Melao ea Tšireletso: Kenya ts'ebetsong mehato e matla ea ts'ireletso ho sireletsa basebetsi le lisebelisoa, ho netefatsa sebaka se sireletsehileng sa mosebetsi.

●Ho kopanya ha mosebetsi: Kopanya mochini oa tjheseletsa molemong oa ts'ebetso ea projeke ka kakaretso bakeng sa ts'ebetso e se nang moeli le tlhahiso e ntlafalitsoeng.

Qetello

Mechini ea tjheseletsa ea liphaephe tsa polasetiki e sebetsang hantle haholo e ntse e fetola tsela eo re atamelang lipeipi tsa polasetiki ka eona, e fana ka lebelo le ke keng la bapisoa, ho nepahala le ho ts'epahala. Ka ho amohela litharollo tsena tse tsoetseng pele, likhoebo li ka fihlela litholoana tse holimo, tsa tobana le liphephetso tsa meaho ea sejoale-joale le merero ea indasteri hang-hang. Ka mochini o nepahetseng le mokhoa oa ho atamela, monyetla oa ts'ebetso e ntlafalitsoeng le boleng bo ikhethang ba ho tjheseletsa phala ea polasetiki ha e na moeli.