Tataiso e ka ho Fetisisang ea Mechini ea Welding ea Pipe ea PE: Khetho, Ts'ebetso, le Lisebelisoa

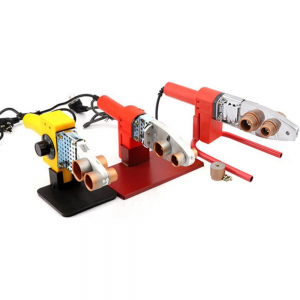

Kenyelletso ea Mechini ea Welding ea PE Pipe

Mechini ea ho tjheseletsa lipeipi tsa PE, e tsejoang hape e le mechini ea butt fusion, e etselitsoe ho kopanya liphaephe le lisebelisoa tsa PE ho theha sistimi e tsoelang pele, e thibelang ho lutla. Ts'ebetso ea tjheseletsa e kenyelletsa ho futhumatsa phala e qetellang mocheso o itseng pele o li hatella hammoho ho theha maqhama a matla, a homogeneous. Mokhoa ona o ratoa ka lebaka la ho tšepahala ha oona le boleng bo phahameng ba li-welds tseo o li hlahisang.

Mefuta ea Mechini ea Welding ea PE Pipe

●Mechini ea ho Welding ea Pipe ea Manual: E hloka hore opareitara a laole potoloho ea ho futhumatsa le ho pholisa. E loketse merero e menyenyane kapa moo ho nepahetseng le ho laola ho leng bohlokoa.

●Semi-Automatic PE Pipe Welding Machines: Iketsetse likarolo tse itseng tsa ts'ebetso ea welding, joalo ka ho beha nako ea ho futhumatsa le ho pholisa, ho netefatsa botsitso le ho fokotsa phoso ea opareitara.

●Mechini ea ho Welding ea Pipe ea PE e Iketselitseng ka Botlalo: Fana ka boiketsetso bo felletseng ba ts'ebetso ea welding, ho kenyelletsa khatello, ho futhumatsa le lipotoloho tse futhumatsang, tse loketseng merero e meholo le ho netefatsa li-welds tsa boleng bo holimo tse nang le ts'ebetso e fokolang ea matsoho.

Ho Khetha Mochini oa Welding oa Peipi oa PE o Nepahetseng

Ho khetha mochini o loketseng oa ho tjheseletsa phala ea PE ho ipapisitse le lintlha tse 'maloa:

●Boholo ba Pipe: Botenya le botenya ba lebota la liphaephe tseo u ikemiselitseng ho li tjheseletsa li tla lekanyetsa boholo le mofuta oa mochini oa tjheseletsa o hlokahalang.

●Sekala sa Morero: Nahana ka boholo ba morero oa hau. Mechini e entsoeng ka letsoho e ka ba le litšenyehelo tse ngata bakeng sa mesebetsi e menyenyane, e etsahalang ka linako tse ling, athe mechini e ikemetseng kapa ea othomathike ka botlalo e loketse mesebetsi e meholo, e etsahalang khafetsa.

●Boemo ba Tsebo ea Opereishene: Mechini e ikemetseng ka ho feletseng e fokotsa tlhokahalo ea basebetsi ba nang le tsebo e phahameng, kaha ba laola boholo ba li-parameter tsa ts'ebetso ea welding ka tsela e iketsang.

●Tekanyetso: Le hoja mechine ea othomathike e fana ka botsitso le katleho e kholoanyane, e boetse e tla le litšenyehelo tse phahameng tsa pele. Leka-lekanya tekanyetso ea hau le litlhoko tsa morero oa hau le melemo ea nako e telele ea katleho.

Malebela a Ts'ebetso bakeng sa Mechini ea Welding ea PE Pipe

● Tokisetso e Nepahetseng: Netefatsa hore liphaephe li sehiloe ka ho lekana le ho hloekisoa hantle pele li tjheseletsa.

● Mocheso o Molemo ka ho Fetisisa: Khomarela litlhophiso tsa mocheso tse khothalletsoang bakeng sa mofuta o khethehileng oa pipe ea PE e cheselitsoeng ho qoba manonyeletso a fokolang.

● Khatello e Nepahetseng: Sebelisa khatello e nepahetseng nakong ea ts'ebetso ea welding ho ea ka litlhaloso tsa mochine le bophara ba pipe.

● Nako ea ho Pholisa: Lumella nako e lekaneng ea ho pholisa tlas'a khatello ho netefatsa ho thehoa ha tlamo e matla.

Likopo tsa Mechini ea Welding ea PE Pipe

Mechini ea welding ea PE e bohlokoa bakeng sa lits'ebetso tse fapaneng, ho kenyelletsa:

● Mekhoa ea Phepelo ea Metsi: Bakeng sa ho theha lipeipi tsa metsi tse tšoarellang tse hananang le khatello ea tikoloho le ho bola ha lik'hemik'hale.

● Mecha ea Phano ea Khase: Ho etsa bonnete ba hore liphaephe tsa khase tse sa duleng tse nang le khanyetso e phahameng ho phatlalatseng mapetsong.

● Tsamaiso ea likhoerekhoere le ea ho ntša metsi: Bakeng sa ho aha likhoele tsa likhoerekhoere tse matla le tse sa duleng.

● Mekhoa ea ho nosetsa: Temong, ho aha marangrang a nosetso a sebetsang hantle le a tšoarellang.

Qetello

Mechini ea ho tjheseletsa lipeipi tsa PE ke lisebelisoa tsa bohlokoa ho aheng le ho lokisoeng ha lipeipi tse tšepahalang. Ka ho utloisisa mefuta ea mechini e fumanehang, ho khetha mochini o nepahetseng bakeng sa litlhoko tsa hau, le ho latela mekhoa e metle ea ts'ebetso, o ka netefatsa bots'epehi le bophelo bo bolelele ba lits'ebetso tsa lipeipi tsa hau tsa PE. Ha tlhoko ea liphaephe tse tšoarellang le tse sebetsang hantle e ntse e hola, karolo ea mechini ea ho tjheseletsa lipeipi tsa PE ho netefatsa hore li-welds tsa boleng bo holimo li ba bohlokoa le ho feta.